2022 Community College Internship (CCI) Program Participants & Projects

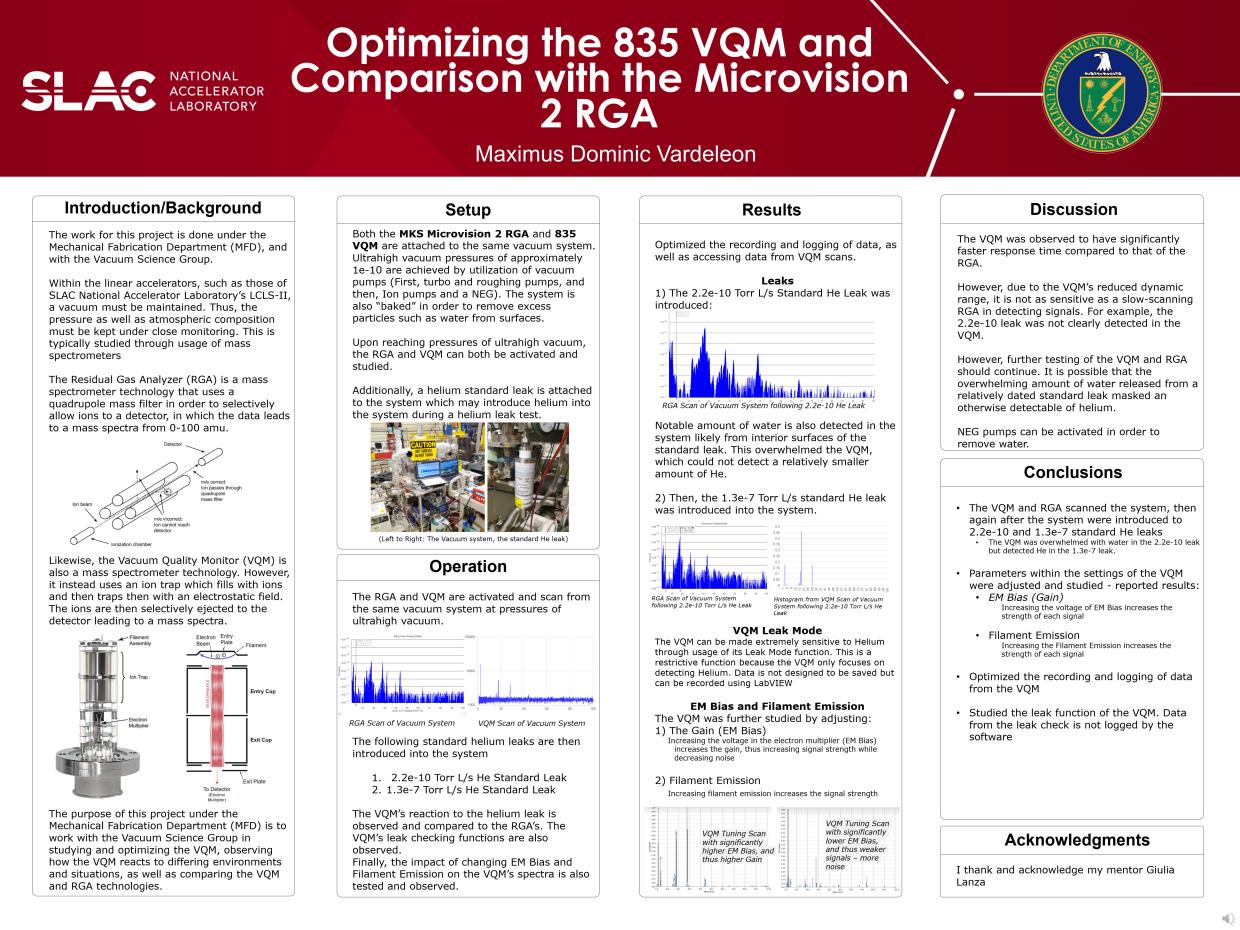

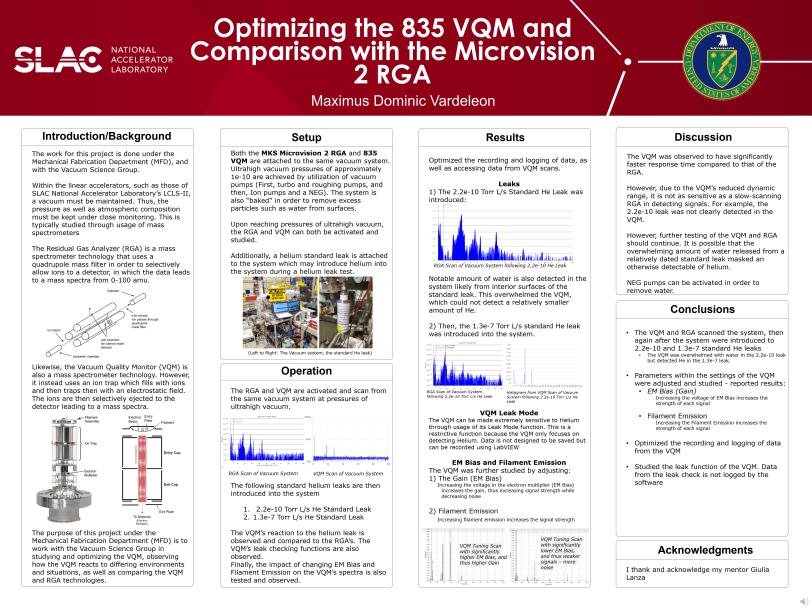

Student: Maximus Dominic Vardeleon

Mentor: Giulia Lanza

Project Title: Optimizing the 835 VQM and Comparison with the Microvision 2RGA

Project Description: Project Description: Within the linear accelerators, a proper vacuum must be maintained to minimize interactions between accelerated particles and the residual gasses. Mass spectrometers are thus utilized to constantly monitor the atmospheric composition within the accelerators. One of these mass spectrometers is a 835 Vacuum Quality Monitor (835 VQM), which utilizes an autoresonant ion trap to determine the relative presence of gasses within a vacuum system. I focused on familiarizing with the 835 VQM and its functions, optimizing the logging of data and opening of saved data, and ran scans testing the VQM’s scanning and testing its reaction to differing environments. These tests were then compared to that of a Residual Gas Analyzer (RGA) another mass spectrometer. Testing was done by having both the VQM and RGA attached to a vacuum system and then scanning at ultra high vacuum. Then, standard Helium leaks (INSERT LEAK RATES) were introduced into the system. In the first test, the VQM could not detect helium possibly due to the fact that water overwhelmed the system. In the second test involving the 1.3e-7 Torr L/s Standard He Leak, both the VQM and RGA could detect the Helium being leaked into the system. In order to decrease the likelihood of water masking the Helium signals, the tests were repeated after installing a NEG. Further testing continued in which Helium was able to be detected by the VQM. In addition, the effects of changing the voltage applied through the Electron Multiplier and changing the Filament emission were studied on the VQM’s capability to scan the system.

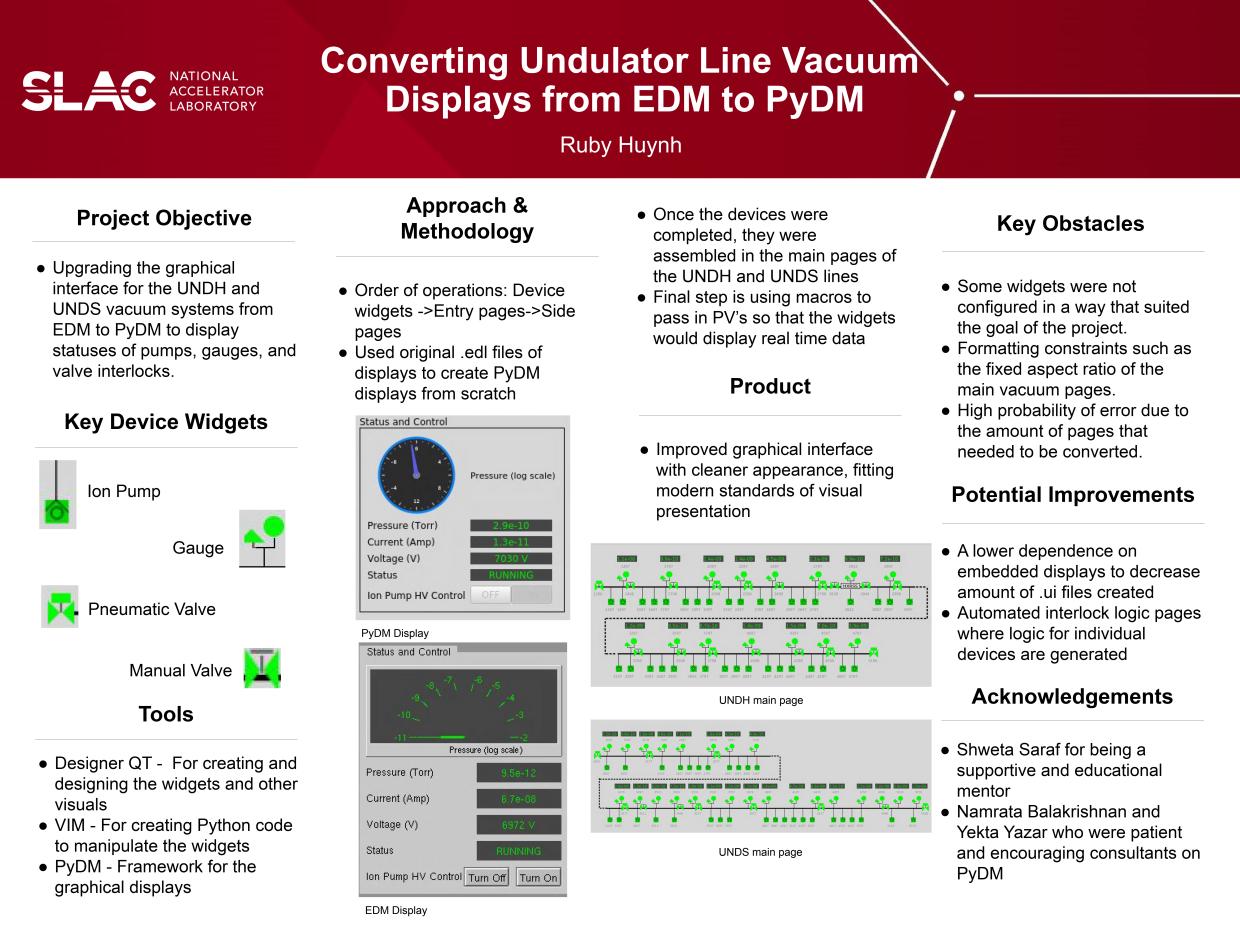

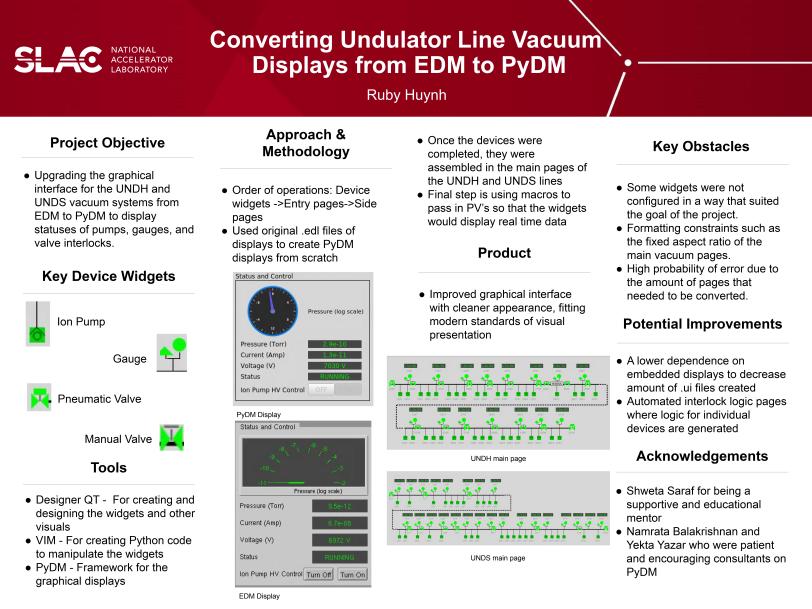

Student: Ruby Huynh

Mentor: Shweta Saraf

Project Title: Converting Undulator Line Vacuum Displays from EDM to PyDM

Project Description: EDM, an EPICS display manager that had been used for the past fifteen years, is no longer supported as of recent, leading to a migration to PyDM, or Python display manager, as the primary framework for graphical displays. Some of the interfaces that required conversion to PyDM were the vacuum system displays for the undulator soft (UNDS) and undulator hard (UNDH) beam lines, which showed the statuses of the ion pumps, gauges, and beamline valves. The interface would show the devices in the vacuum system as being on or off, faulted or not faulted, as well as closed or open. Furthermore, the displays indicate whether the vacuum pressure is below a set threshold that ensures that the interlock statuses are not faulted. Designer QT was used to create the interfaces, and it is a software that allows the user to build a variety of displays and offers the ability to manage widget properties. The different kinds of visuals built, such as the valve interlock logic maps, meters, and representations of the vacuum system devices, were made with this software. The widgets are able to display real-time statuses of the vacuum and the devices with the use of macros, which receive unique variables, called PV’s, that change state based on the device that is inputted. Using the new PyDM graphics display, control operators will monitor the state of the vacuum as well as the devices in the beam lines with an interface that suits existing standards of the control system display as well as modern standards of visual presentation.

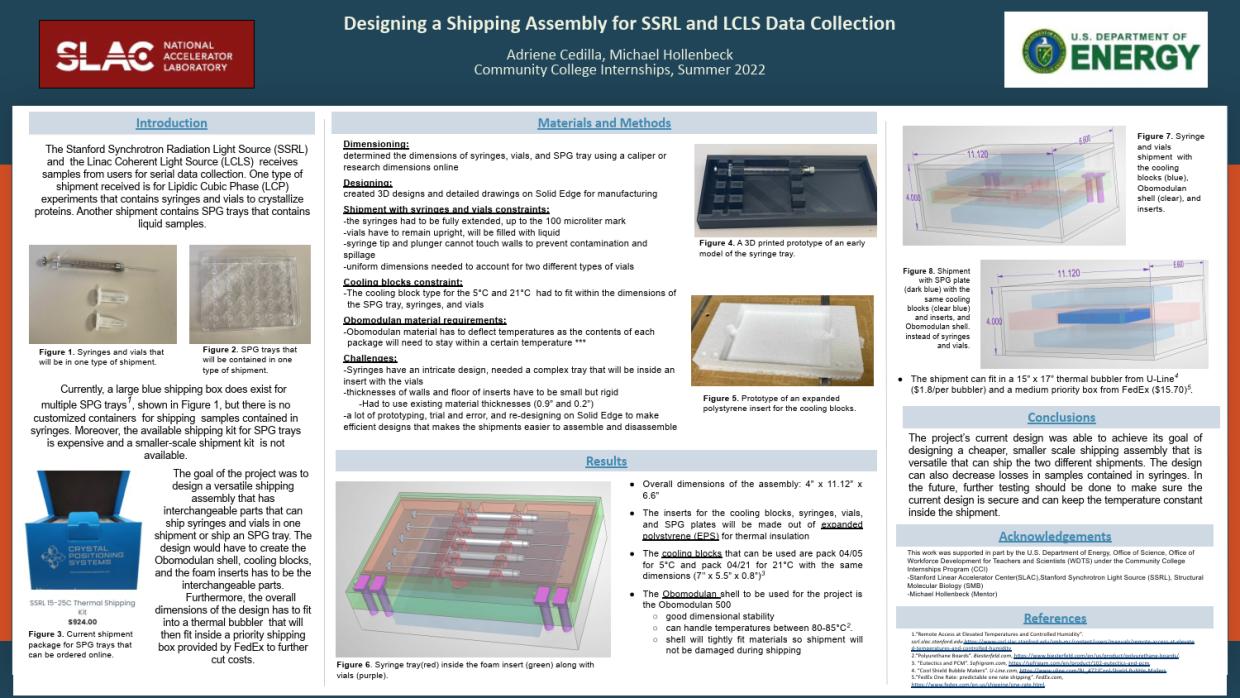

Students: Adriene Cedilla

Mentor: Michael Hollenbeck

Project Title: Designing a Shipping Assembly for SSRL and LCLS Data Collection

Project Description: There are currently no shipping containers for syringes and vials for receiving samples for serial data collection for the Stanford Synchrotron Radiation Light Source (SSRL) and the Linac Coherent Light Source (LCLS).The project’s goal was to design a versatile shipping assembly that can ship out syringes and vials or an SPG tray. The project was done by designing on Solid Edge, 3D printing and machining prototypes, and researching materials and shipping technicalities. The final design was an assembly with expanded polystyrene (EPS) inserts, cooling blocks at 5°C or 21°C, syringes and vials insert or an SPG plate insert, and an Obomodulan shell for rigidity. The assembly fits inside an existing thermal bubbler and a FedEx priority medium box. This design is cost efficient because some materials needed are available at SSRL where the parts can also be machined, and the design potentially decreases losses in shipments due to the customized packaging.